3D SCANNING

We are equipped with. WHITE LIGHT 3D Scanner AS well as Blue light & laser 3D scanner & we provide scanning services to our customers. Scanning prices varies from component to component depending upon complexity and size of the job.

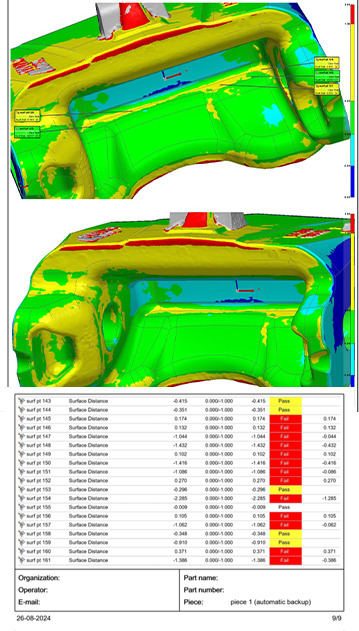

3D Inspection

3D inspection refers to the advanced process of assessing and analysing three-dimensional objects or surfaces using various technologies and methodologies. This technique is increasingly employed across multiple industries, including manufacturing, aerospace, and automotive, to ensure that components meet precise specifications and quality standards. By utilising tools such as laser scanners, structured light systems, and computerised tomography, 3D inspection allows for detailed measurements and visualisation of objects, enabling engineers to identify defects, deviations, or inconsistencies that may not be visible through traditional inspection methods. The ability to capture comprehensive data in a rapid and non-destructive manner enhances productivity and reduces the likelihood of costly errors in production. Furthermore, 3D inspection plays a crucial role in the realms of reverse engineering and product development, where it aids in the optimisation of designs and processes. As technology continues to evolve, the integration of 3D inspection systems with artificial intelligence and machine learning is likely to revolutionise quality assurance practices, making them more efficient and accurate. Overall, the adoption of 3D inspection is becoming essential for organisations aiming to maintain competitiveness and ensure the reliability of their products in today's fast-paced market.

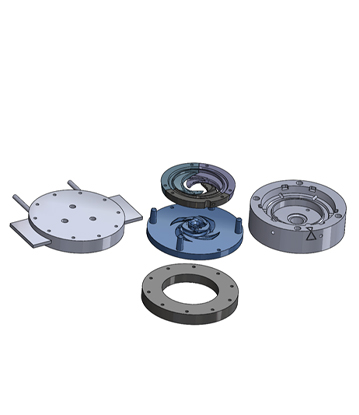

Reverse engineering

Reverse engineering is a systematic process that involves analysing a product or system to understand its components, functionality, and design principles. This technique is commonly employed in various fields, including software development, hardware design, and even pharmaceuticals, where understanding the underlying mechanisms can lead to improvements or innovations. By disassembling a product, reverse engineering allows engineers and developers to gain insights into how it works, which can facilitate the replication of successful features or the identification of potential flaws. Additionally, reverse engineering plays a crucial role in cybersecurity, as it helps to identify vulnerabilities in software systems, enabling organisations to bolster their security measures. While the practice can raise ethical concerns, particularly regarding intellectual property rights, it remains an invaluable tool for fostering innovation and enhancing existing technologies. Ultimately, reverse engineering serves as a bridge between understanding established products and paving the way for future advancements.

3D modelling

• 3D Modeling and Design: Maxmill Technologies delivers precise CAD/CAM designs tailored for industrial applications, ensuring high-quality prototypes and optimized manufacturing processes

• Die &Mold Design: Catering to the die-making industry with robust mold designs that enhance production capabilities

Industry Applications Maxmill Technologies serves diverse sectors with customized solutions: • Power Plants: Providing durable components designed to withstand high-pressure environments.Maxmill's expertise in CAD/CAM can help design and optimize components for power generation equipment, ensuring efficiency and reliability.

• Mining Industry: Developing wear-resistant parts for heavy machinery and operational equipment.The company's solutions can aid in creating durable parts for heavy machinery used in mining operations, enhancing operational efficiency.

If you have any questions or need further information, please don't hesitate to contact us