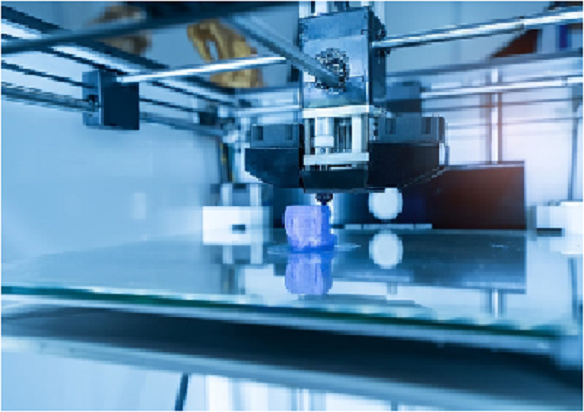

FDM Process

Fused Deposition Modeling (FDM) is a widely used 3D printing technology where thermoplastic filaments are heated and extruded layer by layer to create solid objects. Maxmill Technologies employs this process for prototyping and manufacturing durable components.

Materials Used:

• PLA (Polylactic Acid): A biodegradable material ideal for general-purpose applications.

• ABS (Acrylonitrile Butadiene Styrene): Known for its toughness and resistance to impact, suitable for engineering-grade parts.

• PETG (Polyethylene Terephthalate Glycol): Combines durability with flexibility, making it ideal for functional prototypes and industrial applications

SLA Process

Stereolithography (SLA) uses a laser to cure liquid resin into solid layers, offering high precision and smooth surface finishes. Maxmill Technologies leverages SLA for detailed designs requiring fine accuracy.

Material Used: • PLA Resin: A resin format that provides high detail and smooth finishes, ideal for intricate designs and prototypes

Maxmill Technologies' Expertise

Maxmill Technologies integrates these 3D printing processes into their workflow to cater to diverse industries such as die &mould manufacturing, general machining, and education. Their services include reverse engineering, prototyping, and hands-on training workshops in additive manufacturing technologies By utilizing FDM and SLA technologies alongside their expertise in CAD/CAM/CAE solutions, Maxmill helps clients achieve efficient production cycles, reduced costs, and improved product quality.

If you have any questions or need further information, please don't hesitate to contact us